News

Salt spray test chamber fault judgment and treatment method

!!!!!

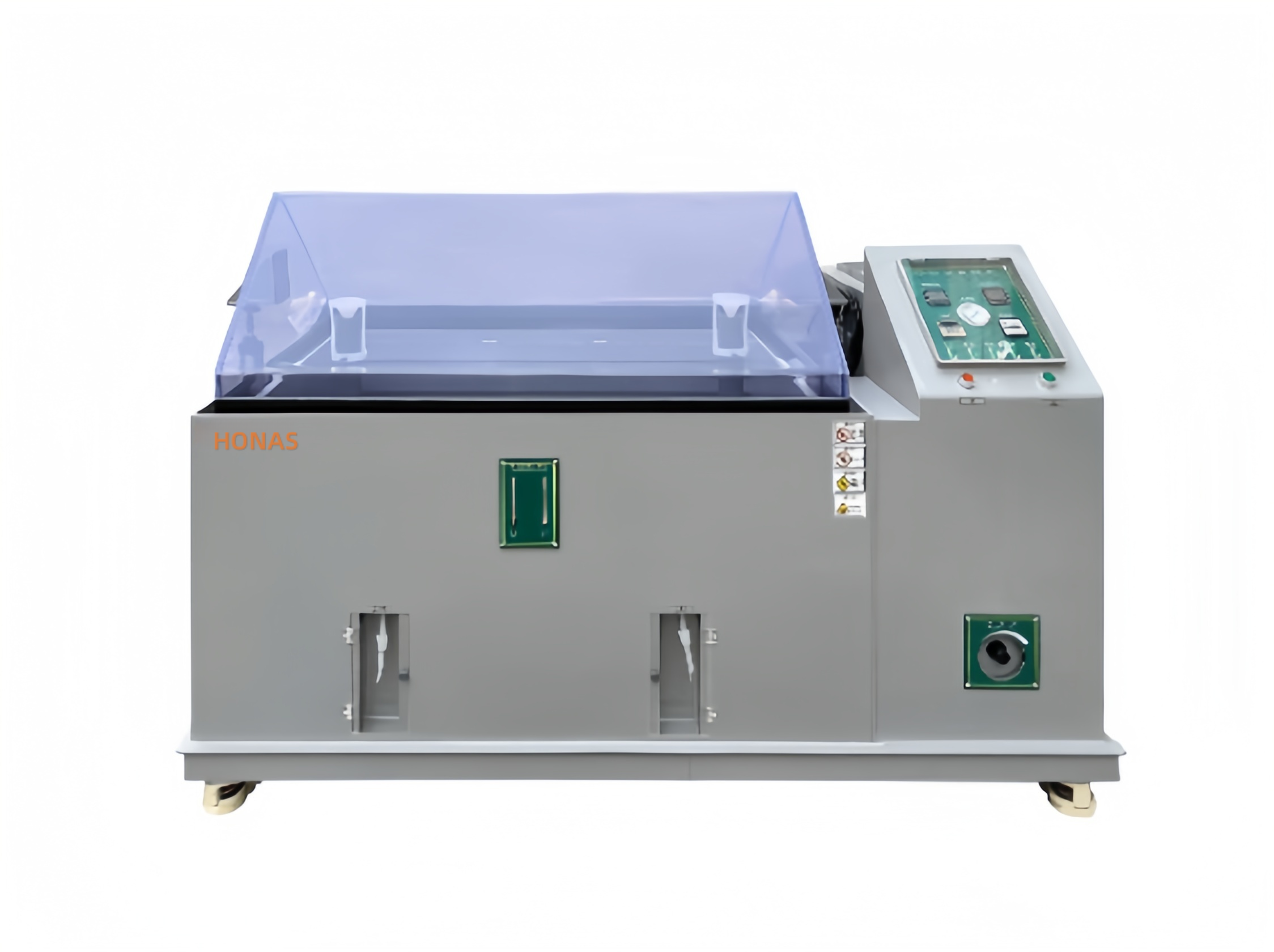

The salt spray test chamber is an important device used to simulate the marine climate environment to test the corrosion resistance of materials. Based on the previous analysis, the following is a detailed method to judge the failure of the salt spray test chamber:

1. Spray system fault diagnosis

1). Abnormal spray volume2). Printhead Problem· Insufficient spray volume : Check whether the spray regulator is placed too low, add salt water to the normal water level in time, and remove the nozzle to clean the blockage.

· Uneven atomization : If the spray is linear rather than conical, it may be due to insufficient air pressure or improper adjustment. Check whether the pressure gauge reading is within the range of 0.2-0.4MPa and adjust the air pressure valve.

· Observe whether the nozzle is clogged and clean it regularly to ensure uniform spraying.

· Check whether the nozzle is installed in the correct position and at an appropriate angle.

2. Temperature control system fault diagnosis

1). Temperature cannot be stabilized2). Abnormal saturated barrel temperature· Check the heating system (such as heating tube) and temperature sensor for damage, and replace damaged parts if necessary.

· Verify whether the temperature controller settings are correct and whether the PID parameters are reasonable.

· Check whether the water level in the saturation bucket is within the normal range and replenish water in time.

· Repair the heating system or replace the temperature controller.

3. Other common fault diagnosis

1). Water seal system leaks2). Abnormal salt mist collection· Check whether the water seal device is intact and whether the sealing ring is aging or damaged.

· Make sure the water seal level is maintained at the appropriate height.

3). Power supply and control system failure· Clean the salt mist collector regularly to ensure uniform airflow.

· Check that the collector is positioned correctly to avoid uneven salt spray deposition.

· Check whether the power connection is normal and the voltage is stable.

· Verify whether the function keys on the control panel are working properly and whether the display is normal.

4. Daily maintenance and preventive measures

1). Regular inspection items

2). Water quality management· Check the brine tank level daily to ensure it is adequate.

· Check the nozzle condition and spray uniformity weekly.

· Check heating system and temperature sensor performance monthly.

3). Environmental requirements·Use deionized or distilled water to avoid impurities affecting spray uniformity.

· Change the saline solution regularly to prevent the solution from deteriorating.

· Avoid installing the device in direct sunlight or near heat sources.

· Ensure the ambient temperature is 15-35°C and the humidity is ≤85%.

Through the above systematic inspection and maintenance, the faults of the salt spray test chamber can be effectively judged and handled in a timely manner to ensure the accuracy of the test results and the long-term stable operation of the equipment.

Website:Shenzhen Honas Technology Co., Ltd.

WhatsAPP:

Categories

Testing refers to a comprehens

2025-09-12

Salt spray test chamber fault

2025-09-10

How to choose the temperature

2020-05-14

Contact

CONTACT USContact:Anna

Phone: +86 14775548318

Email: hns@szhonas.com

Whatsapp: +86-14775548318

Add:805 Jingfa Building, No. 46 Baoqian Lane, Baoqian Road, Baoan District, Shenzhen

Anna

Anna SZ HONAS

SZ HONAS +86-14775548318

+86-14775548318